You have no items in your shopping cart.

In the modern world, where information travels at the speed of light, network cable wiring has become the backbone of communication and data transfer. From homes to businesses, and across continents, cable wiring forms the foundation of our interconnected society. Within these intricate webs of connectivity, various metals play a crucial role in ensuring seamless data transmission and reliable communication. This article delves into the fascinating realm of metals used in cable wiring for network infrastructure, highlighting their unique properties and contributions to the ever-evolving world of technology.

Cable wiring has a rich history, dating back to the early days of telegraphy and telephony. Over time, as technology advanced, so did the materials used in cable wiring. Today, modern network cable wiring has come a long way from the simple copper conductors of the past. The demand for faster data transfer rates, increased bandwidth, and improved signal quality has led to the exploration of new metals and alloys that can meet these requirements.

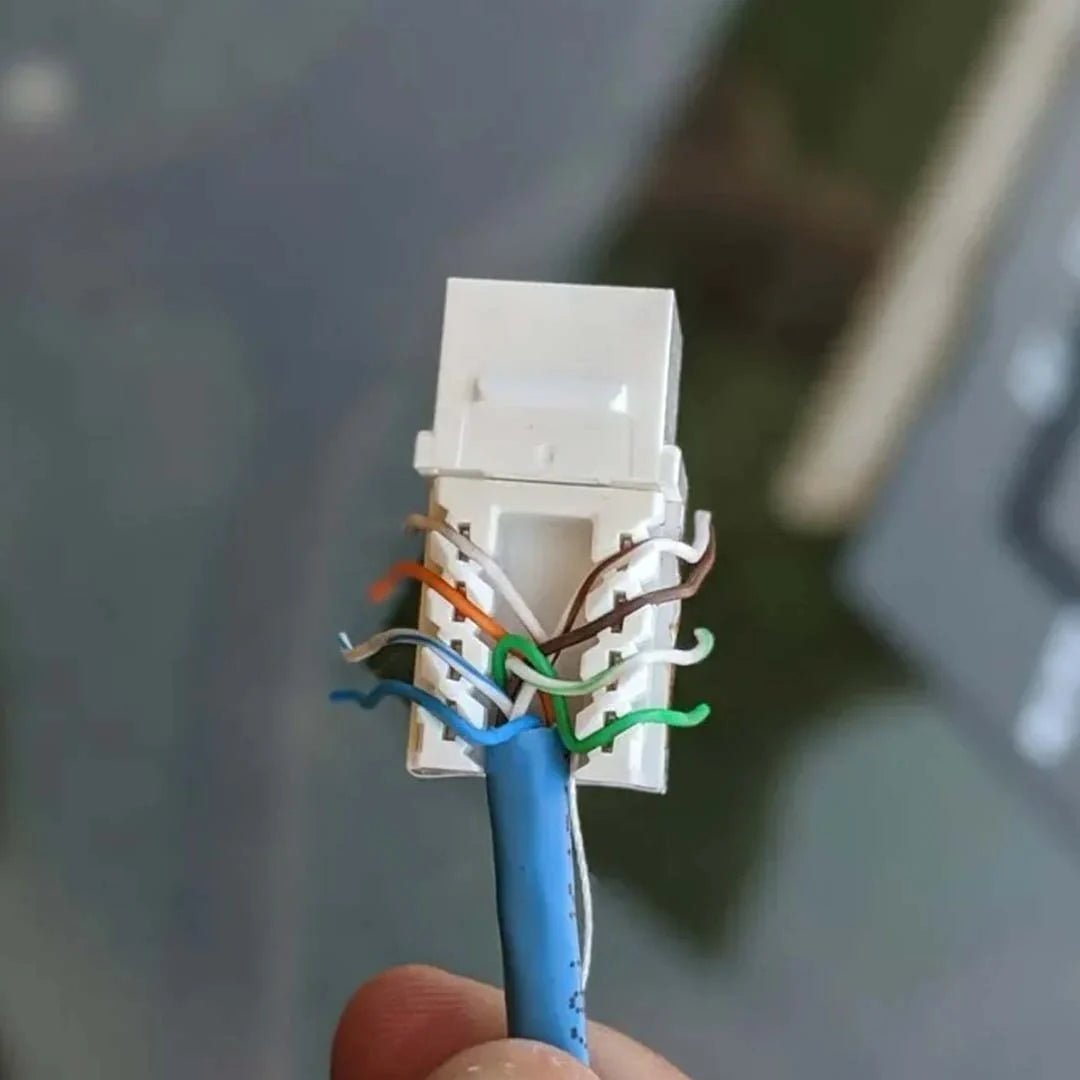

When it comes to cable wiring, one metal has stood the test of time and remains ubiquitous in the field: copper. Copper has been the go-to choice for electrical conductors in cable wiring for decades, and for good reason. Its excellent electrical conductivity, malleability, and affordability make it an ideal material for transmitting signals across short to medium distances. In fact, copper is often used in Ethernet cables, twisted-pair cables, and coaxial cables, all of which form the backbone of local and wide-area networks.

Copper's high conductivity allows for efficient signal transmission, and its malleability enables it to be easily formed into various cable configurations. However, as data transfer rates continue to increase, copper's limitations become more apparent. Signal degradation and attenuation can occur over longer distances, prompting the need for alternative metals and technologies.

As the demand for faster and more reliable data transmission grew, the spotlight shifted to fiber optics—a revolutionary technology that relies on glass or plastic fibers to transmit data using light signals. While not a metal in the traditional sense, fiber optics still play a significant role in modern cable wiring for network infrastructure.

Fiber optic cables offer several advantages over traditional copper cables. Light signals used in fiber optics experience minimal signal degradation, allowing for data to be transmitted over much longer distances without loss of quality. Additionally, fiber optic cables are immune to electromagnetic interference (EMI) and radio frequency interference (RFI), making them an excellent choice for environments with high levels of electromagnetic noise.

In recent years, aluminum has gained attention as an alternative metal for cable wiring, particularly in power distribution and transmission applications. While not as conductive as copper, aluminum's lighter weight and lower cost make it an appealing option for certain scenarios. Aluminum cables are often used in overhead power lines and high-voltage transmission cables, where weight reduction is a critical factor.

However, aluminum's lower electrical conductivity can result in higher resistance and increased heat generation, which may lead to efficiency losses. To address this, aluminum cables often need to be larger in diameter compared to their copper counterparts to achieve the same level of conductivity. Proper installation and maintenance practices are essential to mitigate potential issues associated with aluminum cable wiring.

Copper-Clad Aluminum: Bridging the Gap

To combine the benefits of both copper and aluminum, engineers developed copper-clad aluminum (CCA) wire. CCA wire consists of a solid aluminum core coated with a layer of copper. This hybrid construction aims to provide the conductivity of copper while reducing the overall weight and cost by utilizing aluminum.

CCA wire has found applications in various cable types, including speaker cables and some types of Ethernet cables. However, it's important to note that CCA wire may not perform as well as solid copper in all scenarios, particularly when it comes to high-frequency applications or situations where low resistance is crucial.

Zinc-Coated Steel: Strength and Durability

In outdoor and rugged environments, the cable wiring used for network infrastructure may be subjected to harsh conditions, including extreme temperatures and physical stress. To ensure durability and longevity, zinc-coated steel is employed as a reinforcement material in certain cable designs.

Zinc-coated steel wires are often used as strength members in fiber optic cables, providing support and protection to the delicate optical fibers within. These steel wires enhance the cable's tensile strength and resistance to stretching, bending, and crushing. By incorporating zinc-coated steel, cable manufacturers can create robust cables that can withstand the rigors of installation and environmental factors.

Gold: The Precious Connection

While not a common choice for mainstream cable wiring due to its cost, gold is renowned for its exceptional conductivity and resistance to corrosion. These properties make gold an excellent choice for connectors and contacts within network cable wiring. Gold-plated connectors ensure reliable electrical contact over extended periods, even in environments where oxidation might degrade other metals.

Gold's resistance to corrosion ensures that connectors remain clean and conductive, which is crucial for maintaining optimal signal integrity. This makes gold-plated connectors highly desirable in high-performance audio and video cables, as well as critical data transmission applications.

In the ever-evolving landscape of technology and communication, cable wiring remains an indispensable component of network infrastructure. The choice of metals used in cable wiring plays a pivotal role in determining the performance, reliability, and longevity of these vital connections. From the time-tested copper conductors to the cutting-edge fiber optics, each metal brings its unique attributes to the table, contributing to the seamless flow of data and communication in our interconnected world.

As we continue to push the boundaries of data transfer rates and connectivity, the exploration of novel materials and alloys will undoubtedly shape the future of cable wiring. Whether it's enhancing conductivity, improving durability, or reducing interference, these metals will continue to be the building blocks of cable wiring, driving innovation and enabling the next generation of network infrastructure.

In summary, cable wiring remains the lifeline of modern communication and data transmission, with metals at its core, powering our interconnected world now and into the future. As we navigate the complexities of network architecture, the diverse array of metals used in cable wiring will continue to play a crucial role, shaping the technological landscape and enabling seamless connectivity for generations to come.