You have no items in your shopping cart.

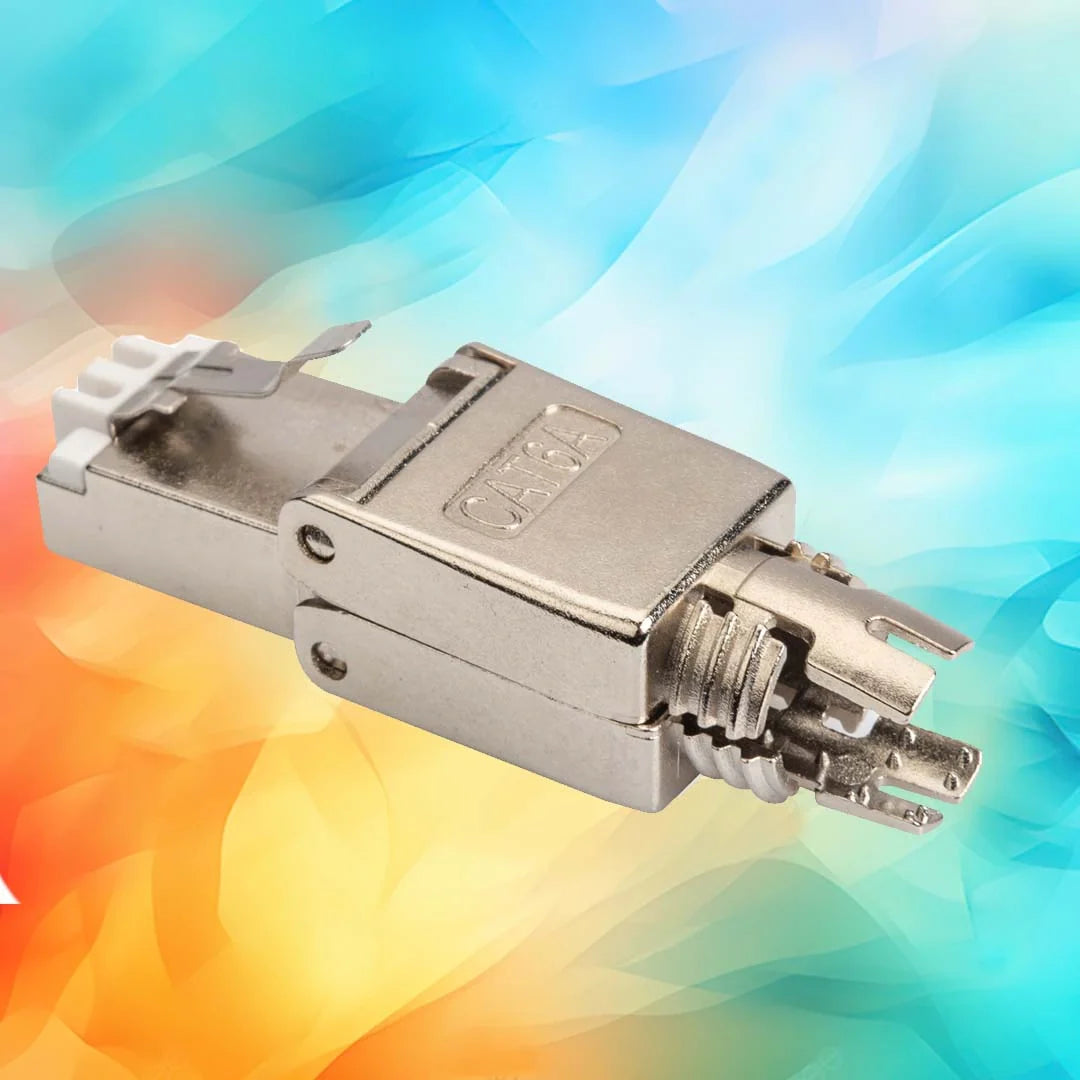

Ending a Cat6A shielded connector plug demands accuracy and a keen eye, for details since this type of connection is commonly found in high-speed networks that demand shielding and resistance to interference from noise sources such as electrical devices or radio signals. In this guide, we'll walk you through all the steps, for correctly terminating a Cat6A shielded connector plug by covering the necessary tools to use the procedures to follow and the recommended practices to guarantee top-notch performance.

Cat6A shielded cables (also known as Category6A cables) are built to support speeds of, up to 10 gigabits per second across distances of up to 100 meters. Perfect for tasks that require reliable data transfer like those found in data centers, networks, and industrial settings. The "shielded " part of a Cat6a shielded cable refers to the added protection layers, around each set of wires and sometimes the whole cable itself. This protective barrier is essential, for reducing interference (EM) and ensuring the integrity of high-speed data transmission.

For network setups where signal interference is a concern and sensitive equipment is used the Cat6A Ethernet cables shielded field termination plug plays a crucial role. Properly terminating the plug is key, to ensuring the shielding's effectiveness, across the system.

Before you start the task of termination procedure ensure you have all the tools and materials.

Make sure the plug you use for Cat6A Shielded Field Terminations is, in line, with Cat6A Shielded specifications. Includes shielding for performance.

Choose the Cat6A shielded cable (either F/UTP or S/FTP) that is appropriate for your setup.

A cable stripper is necessary, for removing the jacket without causing harm to the shielding or wires.

A cable cutter is a tool that is used to trim cable and make a precise cut.

A crimping tool is essential, for fastening the plug to the cable.

Some field termination plugs can be connected without a tool; however, others may need a punch-down tool to complete the connection.

Protective Cover and Casing: These components reinforce the end of the connector to maintain its durability and robustness over time.

Size: Trim your Cat6A shielded cable to the preferred length while making sure to achieve a neat and uniform cut.

Carefully strip off the covering using a cable stripper tool to expose 1 1/2 inches of the outer layer without cutting too deep to avoid harming the shielding or the twisted pairs, beneath it.

Reveal the Shielding. Gently peel off the layer to uncover the twisted inner pairs of wires, inside the cable casing.

Grounding the drain wire; Many Cat6A shielded cables, with shielding have a wire, for grounding purposes; we can set this wire aside gently at this time.

Carefully unwind the pairs. Make sure to unwind each pair of wires in the Cat6A shielded cables as they are usually tightly twisted compared to lower-grade cables; take your time to prevent any kinks or harm to the wires.

Make sure to organize theCat6a shielded cables by following either the T568a or T568b wiring standards when aligning the conductors during your network setup to prevent any connectivity problems due, to wiring practices.

Cut Extra Cable Length. Utilize a cable cutter to neatly trim the conductors to a length, with half an inch of wire exposed for easy fitting, into the plug.

Straightening each wire and arranging them in the sequence required by the selected wiring guideline is crucial. Ensure that all wires are flat and, in line, before inserting them into the Cat6A Shielded plug.

Make sure to open the Plug: If your Cat6A shielded field termination plug comes with a tool design feature it should easily open up to show where you can insert the conductors.

Carefully insert the wires into the specified slots, on the plug while making sure that each wire reaches its position completely and accurately verify the order of the wiring, for precision.

Secure the drain wire by wrapping it around the shielding if it hasn't been done yet to make sure it's properly grounded against the plug's housing.

Secure the Connection. When dealing with tool plugs that do not require tools, for installation or removal simply close the plug over the conductors and shielding by snapping it shut firmly to ensure a connection.

Secure the Plug. Utilize your crimping tool to evenly apply pressure and secure the plug tightly onto the cable. This specific action is crucial to guarantee a Cat6A shielded connection, as a termination could result in signal loss or interference.

To ensure that your Cat6A shielded termination is done correctly follow these steps:

Make sure everything is connected properly. Use a cable tester to check that each wire is connected and there are no breaks or errors, in the connections.

Ensure the Integrity of the Shielding. A cable tester can also verify the continuity of the shielding to ensure that it remains fully intact, along the cable length.

Exploring Problems with Cat6A Shielded Connections

If any of the wires or protective covering becomes loose in a connection setup it could result in loss of connection. Completely cut off the signal flow.

There might be issues, with the connection due to a wire being out of place, in the wiring setup causing network problems.

Make sure that the cat6a shielded and ground wire are properly connected to avoid any interference problems.

Watch out when you're removing the insulation from the wires because if the conductors get damaged in the process it can result in connections or no connection at all.

Recommended Approaches for Cat6A Shielded Field Terminations

Invest in top-notch materials. Opting for premium Cat6A shielded connectors and wiring can significantly boost reliability and effectiveness by minimizing problems linked to signal degradation and disruptions.

Remember to make sure the cable maintains a bend radius to prevent any damage, to the shielding and maintain performance.

Consistently adhere to one set of standards – Choose between the T568 A or T568 B wiring standards, for the network.

Make sure to test each plug before installing it to avoid problems, down the line and save time on fixing issues later on.

Make sure to safeguard the endpoint by utilizing strain relief boots and shielded housing to maintain performance, in settings where there is movement or vibration.

Advantages of Utilizing Cat6A Shielded Field Connectors

Maximize Data Transfer. When you correctly connect Cat6A shielded connectors to the cable ends you can achieve data transfer rates of, up to 10 Gbps for demanding tasks.

Decreased Electromagnetic Interference (EMI) and Crosstalk: Cat6a Shielded protection helps to reduce EMI and crosstalk issues, in crowded network settings.

In the run durability. Cat6a Shielded terminations that are properly shielded are more resilient to wear and tear which makes them perfect, for environments that need a network infrastructure.

In data centers it's crucial to have dependable connections to facilitate data transfers, among servers and network devices.

In settings, the shielding present in Cat6A shielded cables plays a role in safeguarding data integrity, from the strong EMI often encountered in such environments.

For studios and broadcasting stations that rely on broadcasting services for their operations to function smoothly and effectively ensuring high signal quality is of importance. Using Cat6A shielded field termination plugs can significantly contribute to maintaining a consistent transmission of signals ultimately enhancing the performance and reliability of the system.

Healthcare facilities rely on Cat6A shielded cabling to safeguard data networks in areas, with equipment, against disruptions caused by hospital machinery.

Mastery of the termination process for Cat6A shielded field term plugs demands patience and accuracy; however, the outcomes are truly rewarding in the end. Ensuring terminations for Cat6A shielded cables yields connections with high speeds and minimal interference. Crucial in modern high-performance networking setups.

By following the instructions and suggestions provided within this handbook; you will gain the skills needed to achieve dependable and top-notch Cat6A shielded terminations, for your network setups. In high-demand settings, like data centers or industrial sites employing Cat6A shielded cable solutions ensures a speedy network with interference.

A Cat6A Field Termination Plug is a modular connector designed for quickly and efficiently terminating Cat6A Ethernet cables in the field without the need for specialized tools or factory pre-termination.

Cat6A shielded cables (also known as Category6A cables) are built to support speeds of, up to 10 gigabits per second across distances of up to 100 meters.